The future on board –

set your course for efficiency

The Protec Bioreactor is the (bio)logical solution to conventional toilet systems.

Sanitary waste water gets purified while the train is in motion. Whereas a conventional collection tank needs to be emptied every one to three days, an on-board Protec Bioreactor toilet will work non-stop for up to six months. An innovation that pays dividends – thanks to reduced effort, lower operating costs and increased vehicle availability. This guarantees passenger satisfaction – the Protec Bioreactor is a real key to success.

Built for high performance

The Protec Bioreactors have been specially developed for trains – and to work for a train’s entire service life. The system is certified in accordance with the European TSI LOC&PAS guideline. The Protec Bioreactor’s performance is continually monitored during operation.

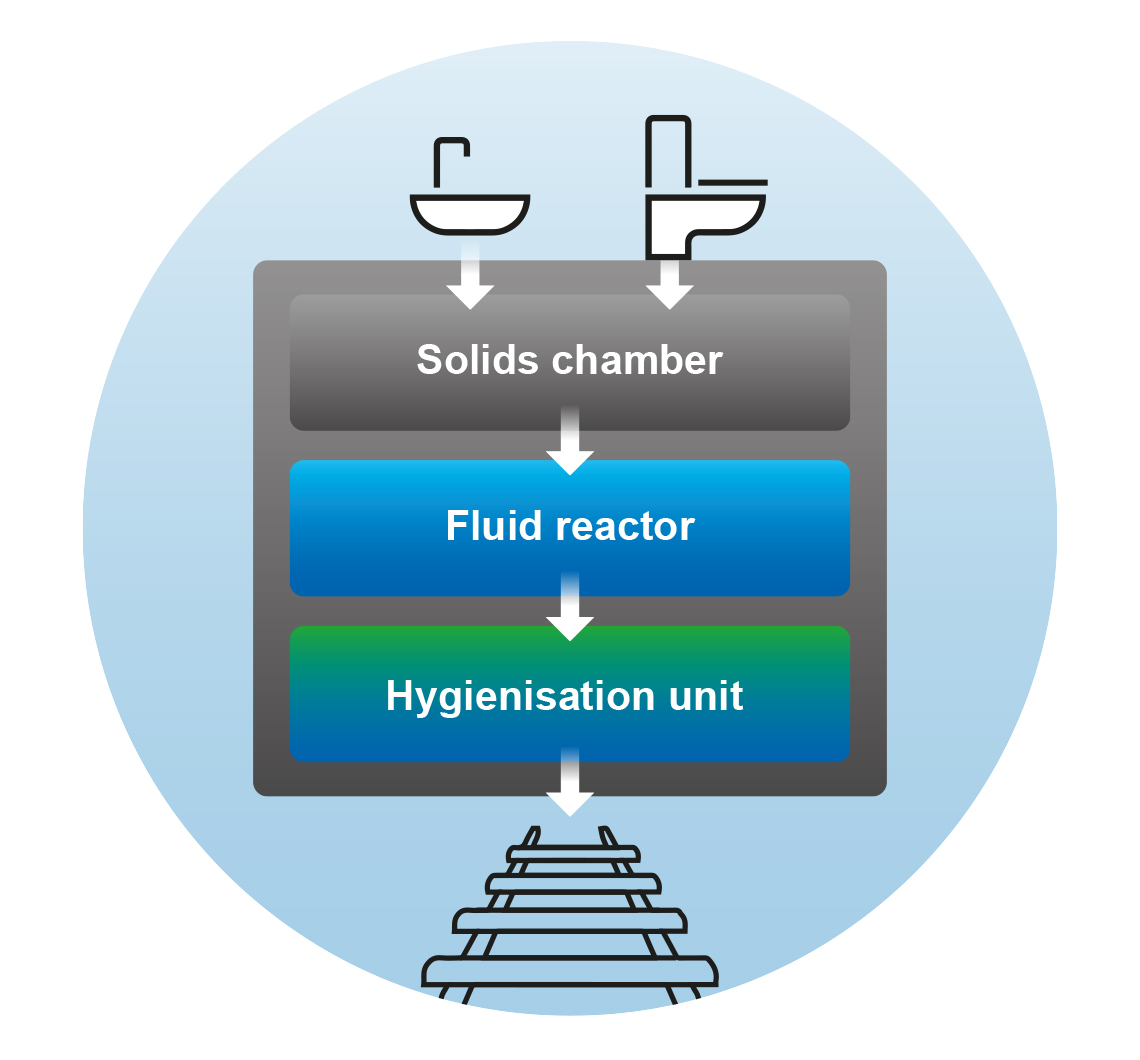

The Protec Bioreactor functional principle

- The first stage of the bioreactor process starts in the solids chamber. First of all, the solid components are separated. Biological decomposition processes then reduce the volume of the solid components to a high degree. The key principle behind this process is to reduce the amount of work required for disposal.

- In the fluid reactor, waste water is biologically treated and purified.

- The final step is the physical, thermal hygienisation: the purified fluid is sanitized without using chemicals; this is all monitored using the latest process technology.

- Once the process is complete, the purified waste water is discharged onto the tracks – only when the train is moving.

Impressive results

- Purely biological/physical treatment: no chemicals or foreign matter are used in the process.

- Purified residual water: regular checks ensure that EU guidelines are adhered to.

- The solid residues can be composted or completely and safely disposed of in the sewerage system.

- Disposal intervals: the residual solid components only have to be disposed of every 2–6 months.

Individuality meets precision

Every Protec Bioreactor is made to measure – and that does not just apply to installation dimensions.

Capacities, specifications and individual services can be tailored to your exact requirements. Discover the benefits of state-of-the-art, high-performance biotechnology.

All with an equally convincing operation and diagnostics concept.

Models

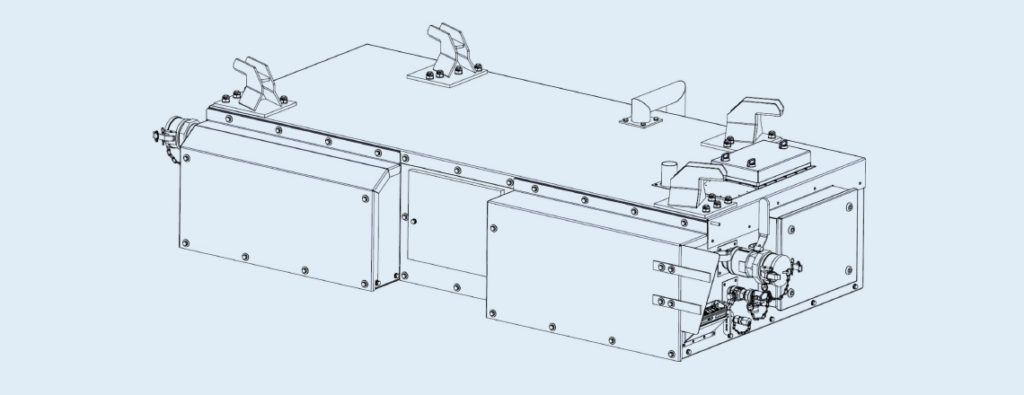

Examples for external installation

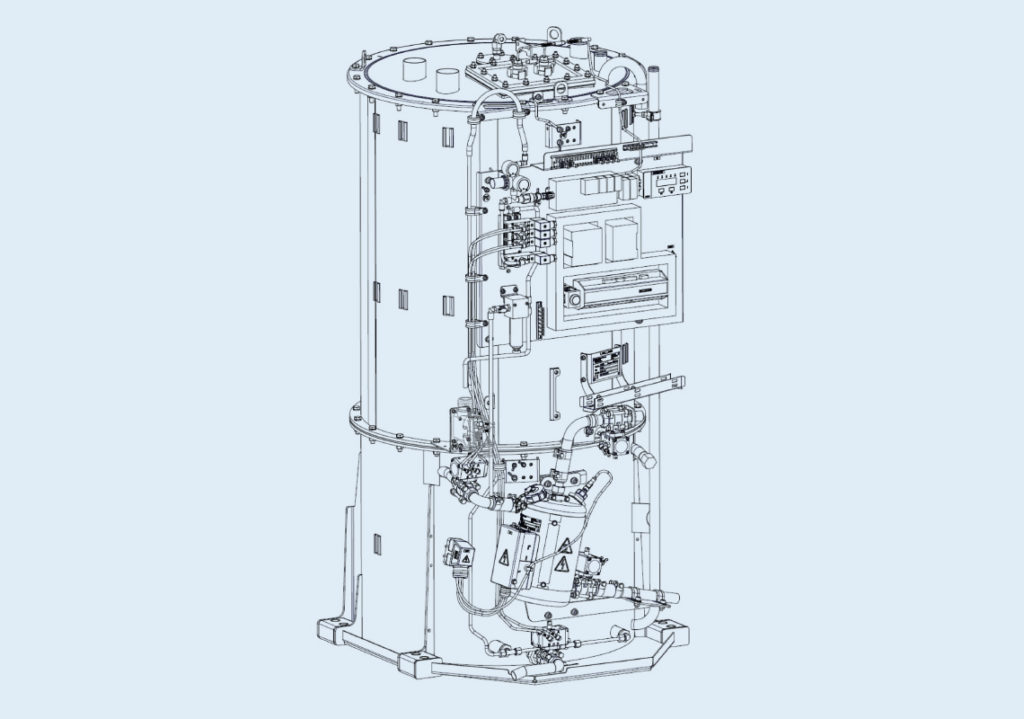

Examples for internal installation

Reliability in daily use

- Operationally reliable

- Consistent water quality

- Fully automatic operation

- Integrated diagnostics

- Can be connected to a train’s control technology or remote monitoring

- Improved hygiene in the depot

- No flammable or explosive gases

- Reduction of odours

Service on schedule

From initial consultation to ongoing operation: we’ll get your solution on track – and guarantee a smooth-running process. All components and services will be customised to perfectly suit your ideas and requirements.

Whether for regional, inter-city or maintenance vehicles: we will work with you to develop an individually tailored concept for water treatment and waste water disposal concept to match your operational model. Our Protec team will support you in all phases of your Protec Bioreactor solution – and, of course, in the planning and implementation of the related disposal infrastructure.

The right tools for perfect handling: to ensure your operations run smoothly, we can equip you with the tools and components that will guarantee professional, convenient use – and seamless operation of the Protec Bioreactor.

Our specialists will handle the installation and commissioning of your Protec Bioreactor. We use testing programs and a range of function tests to provide precise results. We offer expert support during the commissioning of the Protec Bioreactor.

Ready for seamless operation thanks to intensive training. Your maintenance and service team will learn everything they need to know about the Protec Bioreactor: theoretically and hands-on in the workshop. Of course, each Protec Bioreactor comes with a comprehensive instruction manual.

Do you want services and maintenance for the entire lifecycle of your Protec Bioreactor? Our experts can provide on-site support and are just a call away should you have any questions. We will also do any necessary overhauling: send us the component to be reworked and you will receive a replacement part in return. We also offer remote monitoring of your Protec Bioreactor operation, quick troubleshooting and a needs-based maintenance regime.

Even during the planning phase, you will receive an overview of any spare parts required for your Protec Bioreactor that we recommend you keep in stock.

We will provide you with a suitable spare parts supply variant to suit your project phase and logistics concept. Our obsolescence management enables us to ensure the availability of spare parts for the Protec Bioreactor for the entire lifecycle of your vehicle.

Significantly increased efficiency

- Increased vehicle availability

- Long disposal intervals (2–6 months)

- Independent of the standard infrastructure

High

economic efficiency

- Significantly reduced operating costs

- Elimination of external waste disposal costs

- Impressive LCC values

Increased

customer satisfaction

- “Overfilled” toilets will be a thing of the past

- Ready to use around the clock

Convenient

- Reduces the workload for service personnel

- Easy to use

- Comprehensive service concept

High reliability

in daily use

- No flammable or explosive gases

- Reliable operation and consistent water quality

- Increased hygiene

Optimum environmental friendliness

- Tried-and-tested, purely biological principle

- No additives or chemicals involved

- Future-proof water treatment

- Only durable materials such as stainless steel used